Oven Cooking: Application of heat transfer

Fares Al Rwaihy

May 19, 2023

40

1

Heat transfer plays a vital role in the cooking process, transforming raw ingredients into delicious masterpieces. Understanding the application of heat transfer principles in oven cooking is essential for achieving optimal results.

13 min read

Introduction

As enthusiasts of the culinary arts, we know that cooking is both an art and a science. The precise control of heat is the key to transforming raw ingredients into delectable meals. By understanding the fundamental principles of heat transfer and how they apply in oven cooking, we can unlock the secrets to culinary excellence.

*Introducing FEA Thermal Analysis: A Comparison to Hand Calculation

**Thanks to Ansys innovation courses for enhancing this blog with an idea

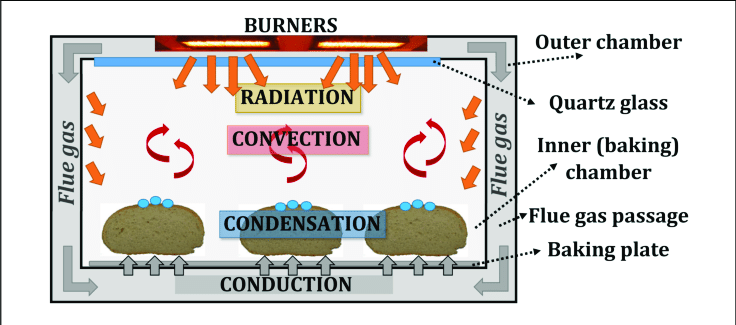

Heat Transfer Modes: Full Oven Analysis

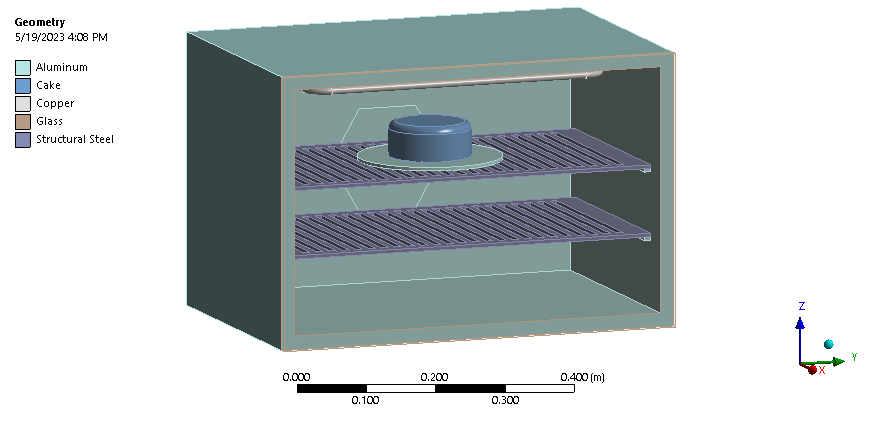

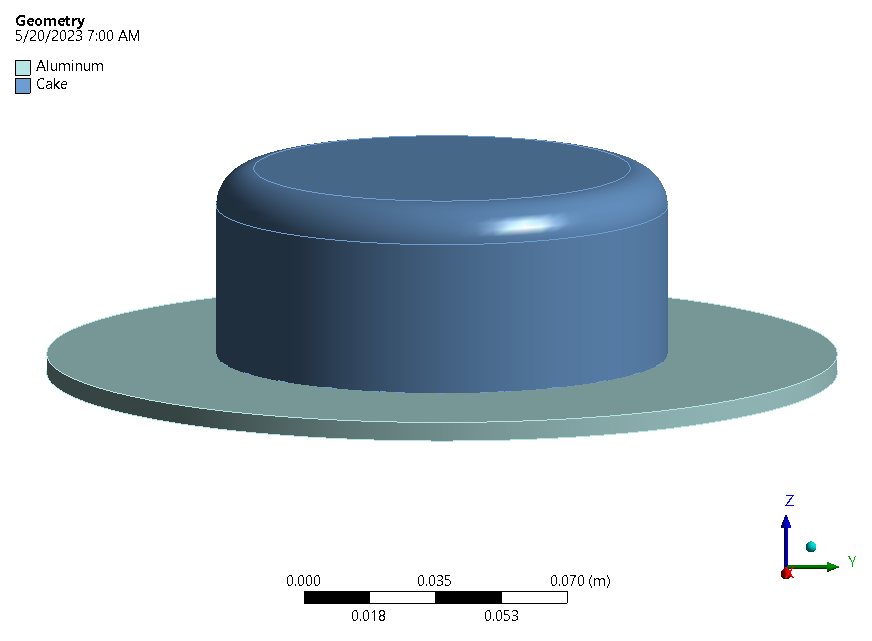

The following table shows all the parts on which we will conduct our thermal analyses:

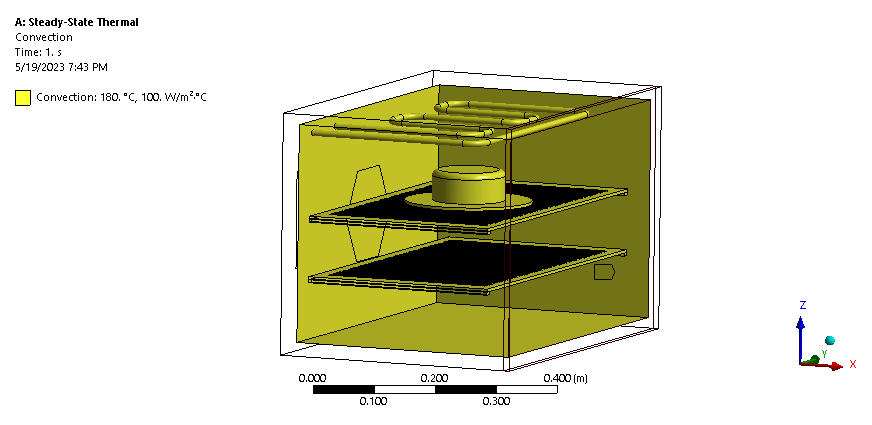

Visual representation:

Boundary Condition

Assuming the oven is already preheated in which the intensity heat is remaining constant, so Steady-State thermal analysis will take a place. However, in order to fully capture all necessary heat we need to investigate the effect of each type of heat transfer.

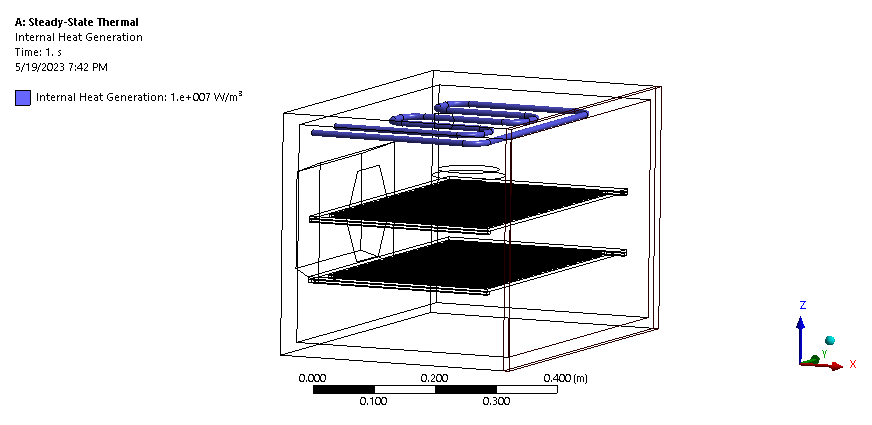

Internal Heat Generation:

The working principle involves the conversion of electrical energy into heat energy through resistive heating elements. These elements generate heat when an electric current passes through them, which raises the temperature within the oven cavity. The heat is then transferred to the food through conduction, convection, and radiation, resulting in the cooking or baking process. However, for electric oven there are upper exposed coil (burner) and hidden lower coil.

**Exposed burner will lead to more browning and less heat uniform

Thermal Conduction:

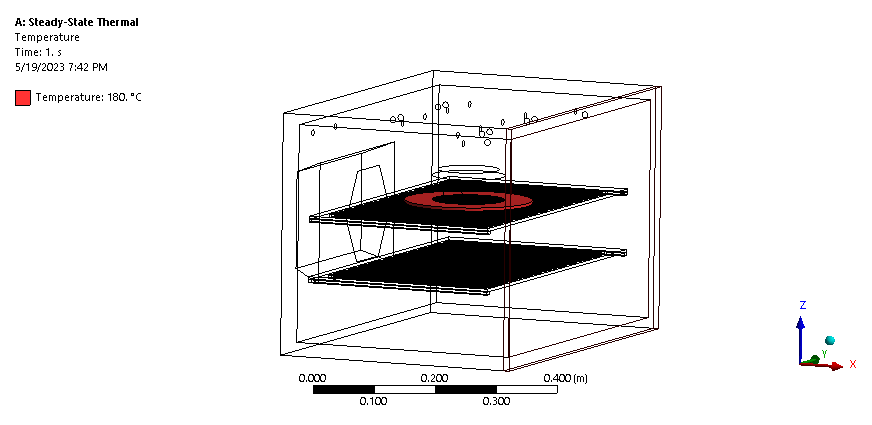

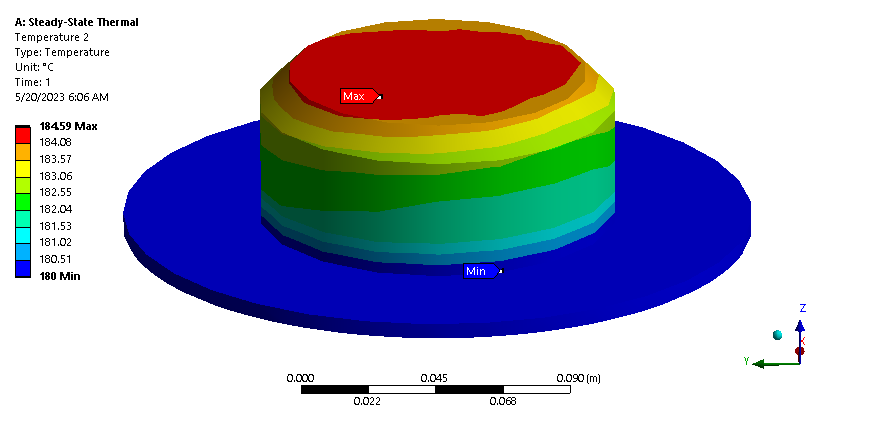

In this case, the plate on which the cake is placed has been preheated to 180 degrees Celsius. When the cake comes into direct contact with the plate, there will be thermal conduction, which refers to the transfer of heat through direct contact between objects with different temperatures. The heat will flow from the hotter plate to the cooler cake through the process of conduction.

Thermal Convection (Internal Oven Side):

This refers to the convection that occurs within the oven due to air recycling. It can be either forced convection, where a fan is used to circulate the air, or regular convection. The bulk temperature of these parts is 1800c. The boundary condition for all thermal types will be specified in a table.

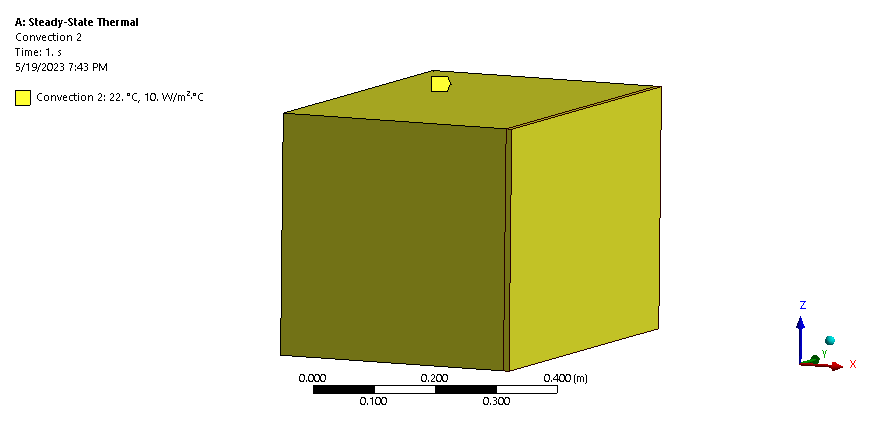

Thermal Convection (Outer Oven Parts):

This involves convection occurring on the outer surfaces of the oven. There are four aluminum sides and one glass side. The bulk temperature of these parts is 220c, indicating the temperature after the dissipation of the oven's heat energy. This temperature corresponds to the ambient temperature of 22 degrees Celsius.

Thermal Radiation:

The heat generated within oven goes to all inner component of its wall and the concept is how much of these heat being emitted. For the simplicity of this simulation 0.5 emissivity was assigned to all parts as one unit material.

Emissivity is a measure of how well a surface emits thermal radiation compared to an ideal black body, which has an emissivity of 1.0 (perfect emitter). Ovens typically have surfaces with relatively high emissivity values, as they are designed to radiate heat efficiently. The emissivity of common oven materials such as stainless steel, aluminum, or cast iron is typically around 0.8 to 0.9, meaning they emit thermal radiation at around 80% to 90% efficiency compared to a black body.

**Uses the same internal oven sides as convection

Results

The cake is cooked in 180 degree Celsius. However, applying all of the previous Boundary conditions will lead to variation of temperature inside the oven here is the three main parts results:

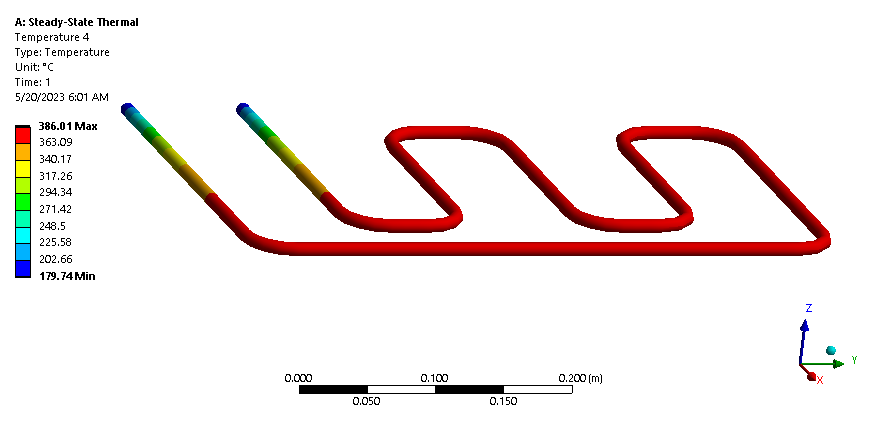

- Temperature of Grill: The generated heat from the hexagonal grill's pipe may exceed the set limit temperature of 180 degrees Celsius, which is detected by a sensor to stop the oven. It is normal for the generated part inside the oven to have a higher temperature than 180 degrees Celsius. However, the oven temperature itself is about 180 degrees Celsius, indicating that the oven is functioning within the desired range.

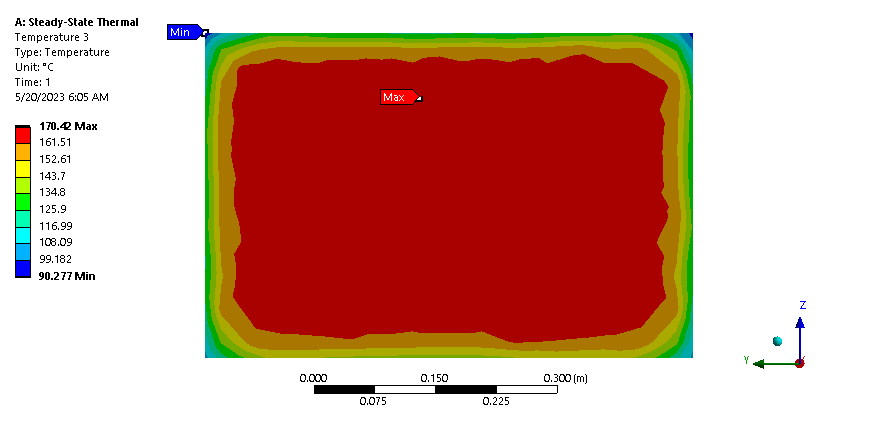

- Temperature of Oven Glass: The glass material of the oven will have a different temperature distribution compared to the other wall sides of the oven. The task is to ensure that the selected glass material can withstand these temperature variations. It is important to choose a glass material that is suitable for the intended temperature range to prevent any damage or failure.

- Temperature of Cake: The main objective of the thermal analysis is to bake the cake at a temperature of 180 degrees Celsius. This indicates that the desired baking temperature for the cake is being achieved.

- Radiation Probe: Additional to the Temperature, Electromagnetic waves are a form of radiation that travel though the oven. Ansys Software gave an answer showing on the table

And it can be calculated as the follow:

Thus,

Heat Transfer Modes: Individual Scope Analysis

To conduct an individual scope analysis of heat transfer modes in different ovens, we will focus on one specific boundary condition: comparing the time taken to heat a cookie to a temperature of 180℃ and the uniformity of temperature distribution in the cookie. This analysis will require a thermal transient analysis, which involves studying how the temperature changes over time.

Visual representation:

Boundary Condition

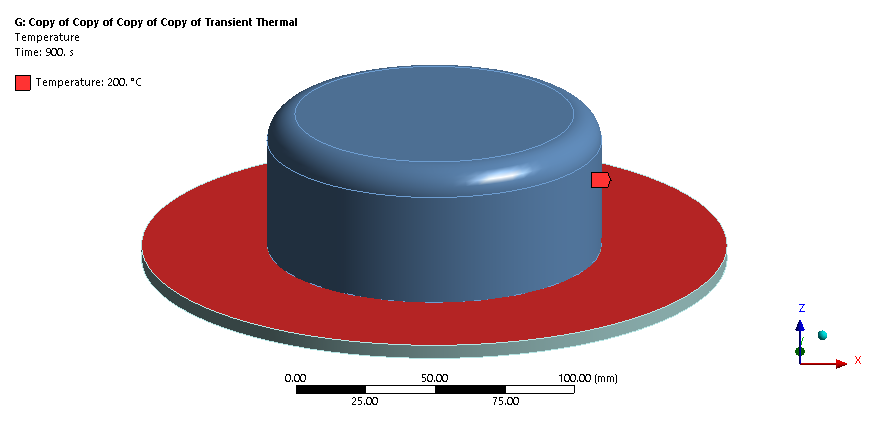

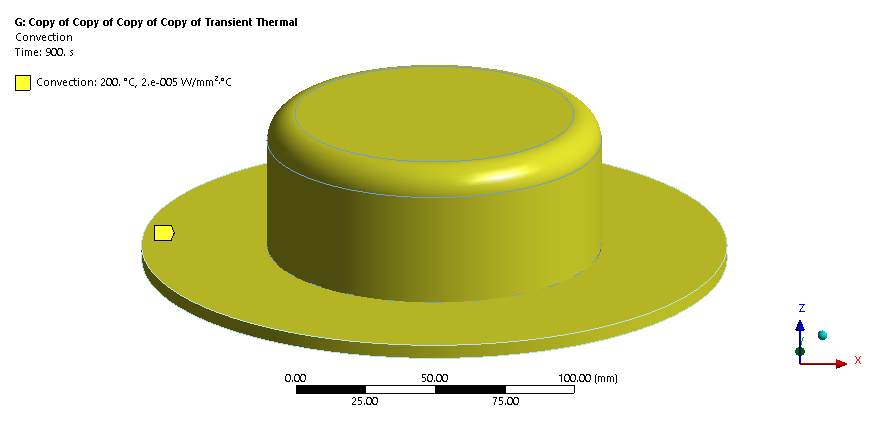

By considering the following three heat transfer modes, we can simulate and analyze how each oven type influences the time required to reach a temperature of 180℃ and the resulting uniformity of temperature distribution in the cookie.

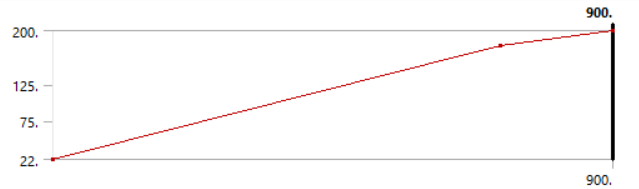

Assuming a source of thermal radiation that heated the parts up, thus

- Conduction:

- Convection:

- Radiation:

** Oven heated in this way in which it took 12 minutes to reach 180 Degree Celsius then the remaining to reach 200, following most of market ovens.

Conventional:

Conventional ovens heat up food primarily through radiation from the heating elements. The movement of air due to natural convection, Three cases could be demonstrated here

- Basic Conventional: In this scenario, we start with a room temperature oven. As time passes, the heating elements generate radiation, which is absorbed by the plate holding the cake. The plate then transfers heat to the cake through conduction.

- Preheated oven: In this case, the oven is already preheated to a certain temperature. The plate holding the cake is added to the oven, and the oven's higher temperature transfers heat to both the plate and the cake. Conduction then takes place from the plate to the cake, ensuring heat is evenly distributed.transfer heat to cake and plate which will perform conduction to cake.

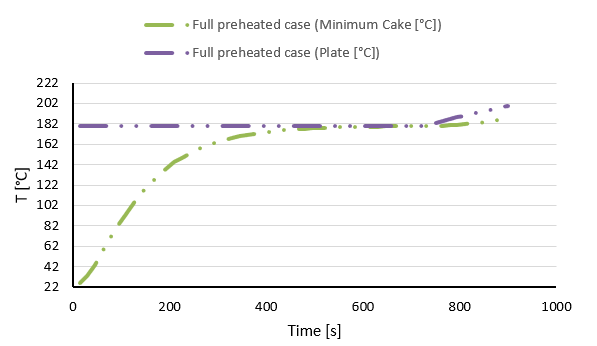

- Full preheated case: In this scenario, not only is the oven preheated, but the plate itself is already heated up along with the oven. This eliminates the need for additional heating of the plate. The focus here is solely on heating up the cake, with conduction playing a crucial role in the transfer of heat from the plate to the cake.

Forced convection:

(if the oven has a fan) will affect the heat transfer to the cookie. Convection helps distribute the heat evenly within the oven and influences the rate at which the cookie heats up.

By introducing the fan, the airflow within the oven is enhanced, resulting in improved convection and a more uniform distribution of heat. This can significantly impact the time taken for the cake to reach the desired temperature and ensure consistent baking throughout. To achieve this, i modified the convective heat transfer film coefficient, which represents the intensity of heat transferred per square meter for each Celsius degree.

Grill Radiation:

In an oven, radiation is primarily responsible for heat transfer from the oven walls and heating elements to the cookie. The emissivity of the oven's interior surfaces and the absorption properties of the cookie dough will influence the radiation heat transfer.

Results

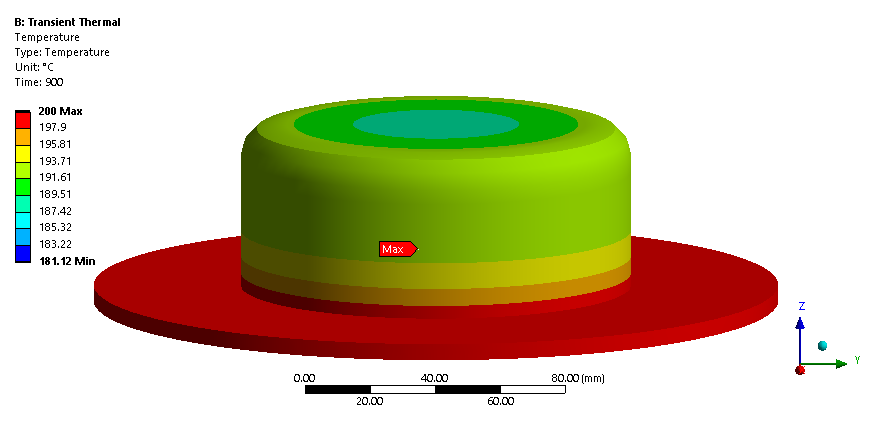

Our objective here is to determine the time required for each different oven mode. While it may be challenging to visually observe the temperature distribution to understand the differences, we can still analyze the time taken for each mode. Let's consider an example of one mode:

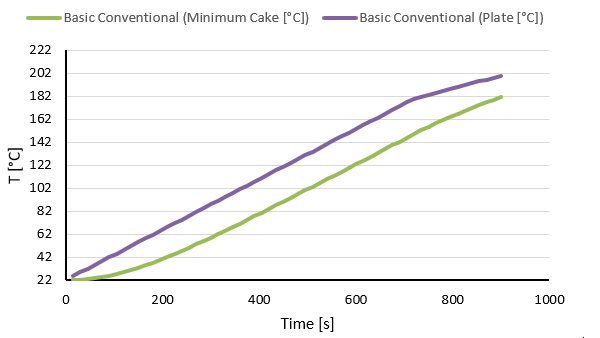

And also taking conventional as an example to understand the variation in time we can see how is the time varying between Basic Conventional and Full Preheated Case

- Basic Conventional:

- Full preheated case:

Thus, Having all Temperature, and Time Graphs we can make this table:

Discussion

The first three modes follow the same concept of heating the cake in a conventional oven but with different configurations. It is interesting to observe how changes in the oven configuration can lead to significant time savings. For example, when comparing the Basic Conventional mode to the Full Preheated Case, there is a visible reduction in time from 890 seconds to 765 seconds. Preheating the oven and the plate allows for faster heat transfer, resulting in a shorter baking time.

Furthermore, it is important to consider the temperature of the plate during baking. In the example given, the plate temperature was 199 degrees Celsius, while the desired minimum temperature for the cake was 180 degrees Celsius (the baking degree of the cake). This temperature difference suggests that there may be a contact point between the cake and the plate that reaches approximately 199 degrees Celsius, potentially resulting in a burned side of the cake. It is crucial to ensure proper insulation or use of suitable materials to avoid uneven heating.

Additionally, the analysis indicates that it took only 250 seconds to reach a temperature of 170 degrees Celsius, while the remaining time was primarily spent reaching the final temperature of 180 degrees Celsius. This observation highlights the importance of monitoring the baking process to prevent overcooking or undercooking the cake.

The other three modes, which incorporate a fan inside the oven, follow the same concept but are faster due to the more effective heat distribution facilitated by the fan. The improved convection resulting from the fan's airflow ensures more uniform heating, leading to reduced baking times.

Lastly, when applying an external mode, such as adjusting the emissivity, there is a noticeable time reduction. Emissivity affects the absorption and emission of heat energy, and optimizing it can lead to more efficient heat transfer and shorter baking times.

Summary

The most efficient method for baking, in terms of time, is to utilize both the grill radiation and the Full Preheated Case Forced Convection. This approach combines the radiation effect of the grill with the use of the oven's fan in a preheated environment. As previously shown, the temperature reaches 170 degrees Celsius in significantly less time compared to the values mentioned in the table, which correspond to reaching a temperature of 180 degrees Celsius. However, it's important to note that using the grill is not ideal when baking cakes as it can lead to uneven heating. The grill radiation is more suitable for baking biscuits or other similar baked goods that require direct heat from above. Additionally, the fan may not be the best option when baking cakes, as the desired heat distribution is often more focused on the bottom of the cake to ensure proper rising.

By understanding the different heat transfer modes and their effects, we can optimize the baking process and achieve the desired results for various types of baked goods.