Design of a Belt Conveyor

The project aims to design a belt conveyor for bulk material handling in various industries, following the RULMECA catalog guidelines for rollers and components, and meeting the ISO 9001/2000 quality management system standards for reliability, efficiency, and safety.

90

1

Introduction

The design of a belt conveyor for bulk material handling is a critical task in industries. The efficient movement of materials is essential for the smooth operation of these industries. To ensure the reliability, efficiency, and safety of the conveyor, it is important to follow established guidelines and standards. In this project, we will be designing a belt conveyor based on the RULMECA catalog, which provides a range of rollers and components specifically designed for bulk handling systems. The design will also comply with the ISO 9001/2000 quality management system standards, which will ensure that the conveyor is built to high-quality standards and will meet the needs of the industry. The successful completion of this project will result in a conveyor that is reliable, efficient, and safe for the transportation of bulk materials.

Objectives

- To develop a belt conveyor that meets the RULMECA catalog standards for rollers and components in bulk handling systems.

- To guarantee that the design meets the quality management system standards ISO 9001/2000.

Task set-up (step1):

For each new design, we have what we call key deliverables, in which we establish our scope based on these keys. It consists of the outcomes needed from the task, and they can be seen in the following table.

Predetermination the belt speed, choosing a carrying troughing set and belt width (𝑣=?, λ=?, WB=?) (step2):

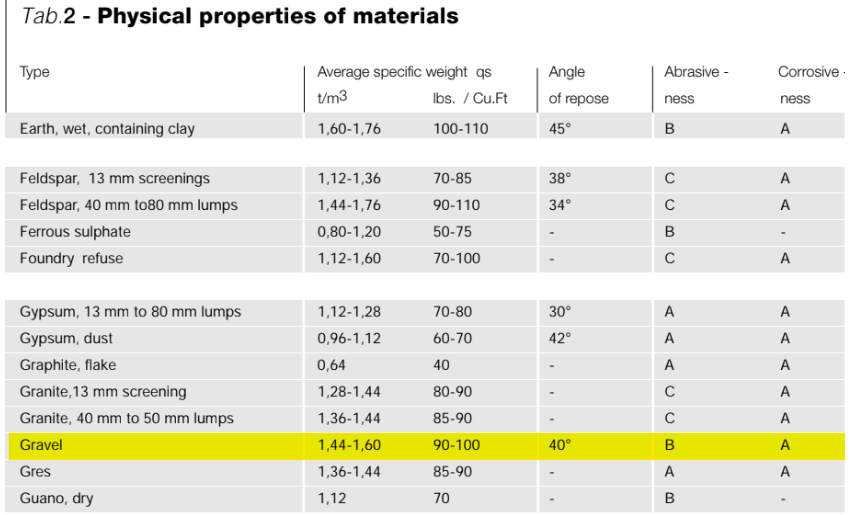

The physical properties of the conveyed material

Calculating the volumetric load Ivt

Where;

- Im is the required volumetric load of the conveyor

- 𝑣 is the belt speed

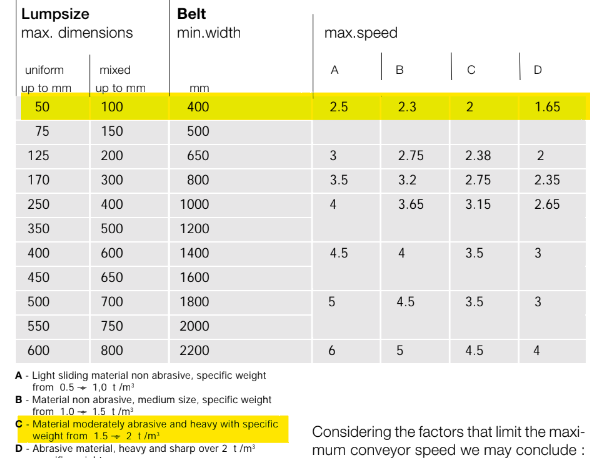

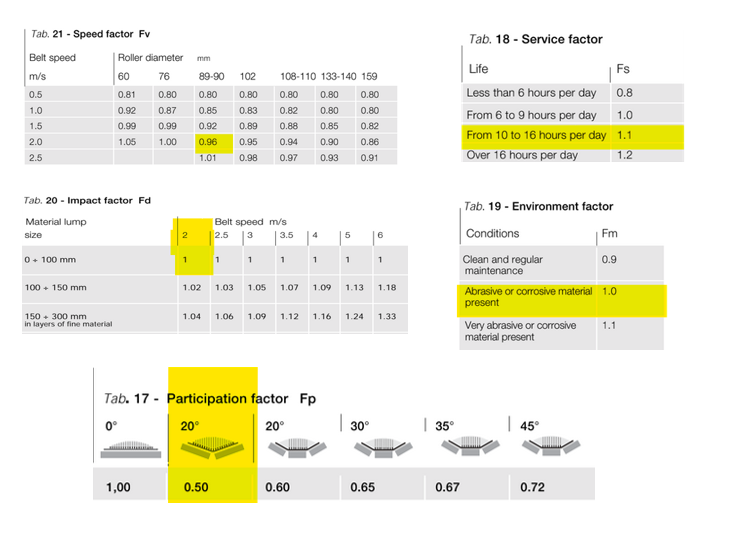

From the table the maximum advised belt speed and minimum belt width depend on the lump size and specific weight of the material 𝑣 = 2 [m/s]

- K is the correction coefficient due to the inclination of conveyor , K1 is the correction coefficient due to the irregularity of feed

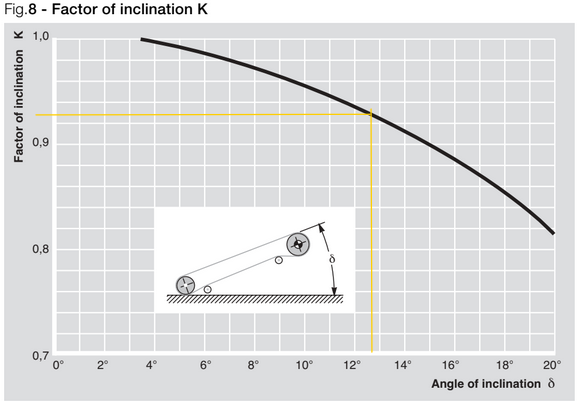

The angle of inclination

The correction coefficient due to the inclination is K = 0.93

The correction coefficient due to the irregularity of feed is K1=0.90

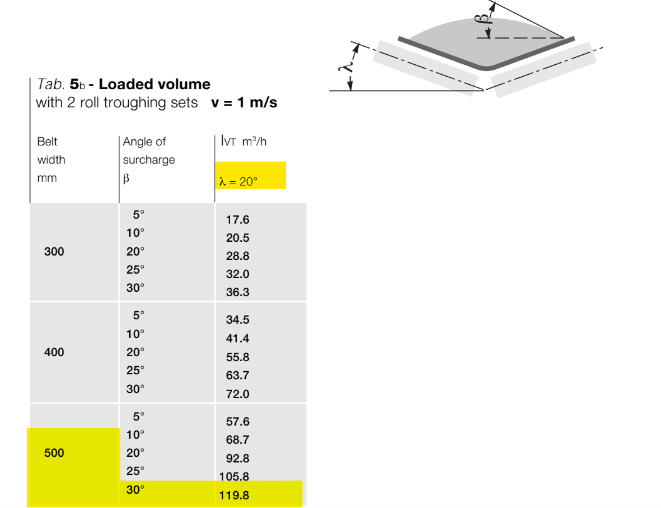

Selecting a carrying troughing set and belt width

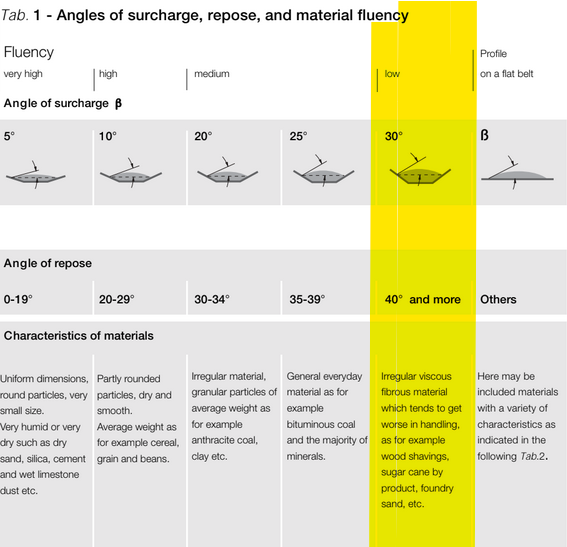

From the physical properties of the conveyed material, the angle of response is 40° which lead to the Angle of surcharge β = 30°

The minimum belt width depending on the loaded volume is expressed relevant to the speed of 1 [m/s] and into consideration the belt width from previous table and choosing the highest value

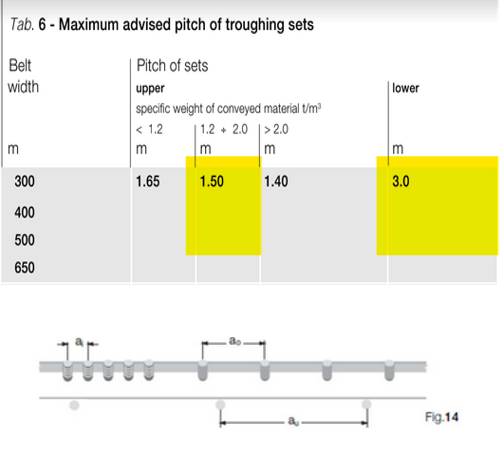

Determine the maximum pitch of roller sets (𝑎𝑜=?, 𝑎𝑢=?) (step3):

The maximum pitch of troughing sets depending on the belt width and specific weight

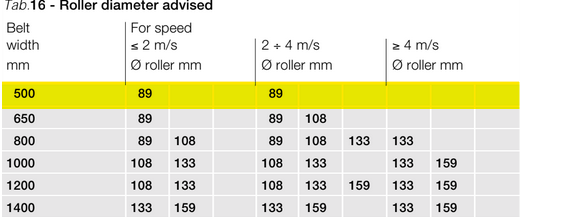

Determine the diameter of rollers

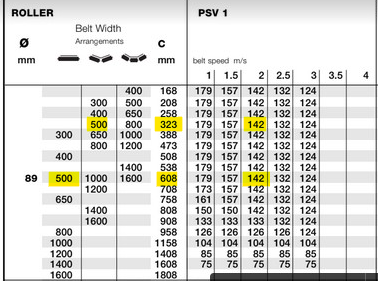

The diameter of rollers depending on the belt width and speed DR = 89 [mm]

selecting the rollers

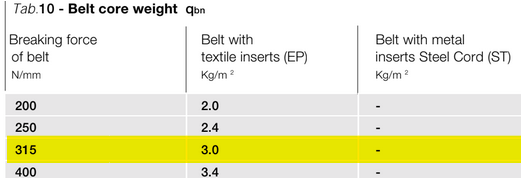

The belt core weight

The total belt weight

Calculate the load on the carrying strand and the return strand (𝑐𝑎=?, 𝑐𝑟=?) (step4):

The static load for carrying rollers

The dynamic load for carrying rollers

The load on the central roller of a carrying troughing set

Where;

The static load for the return rollers;

The dynamic load for the return rollers;

The load on the return roller

Selecting the rollers

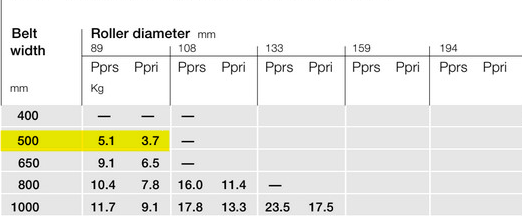

Rollers for carrying idlers type PSV/1 diameter = 89 with bearing 6204 of length C = 323 with load capacity 142 kg that satisfies the required loading of = 25.69kg

or

Rollers for carrying idlers type PSV/1 diameter = 89 with bearing 6204 of length C = 608 with load capacity 142 kg that satisfies the required loading of = 7.695kg

Determine the motor power to move the belt conveyor (𝑃=?) (step5):

The weight of rotating part of the rollers

1. Upper rotating part

2. Lower rotating parts

The weight of conveyed material per linear meter is

The total tangential force at the drive pulley periphery is

The efficiency of the reduction gear and possible transmission is n = 0.86

The necessary driving power is